Slide

Slide

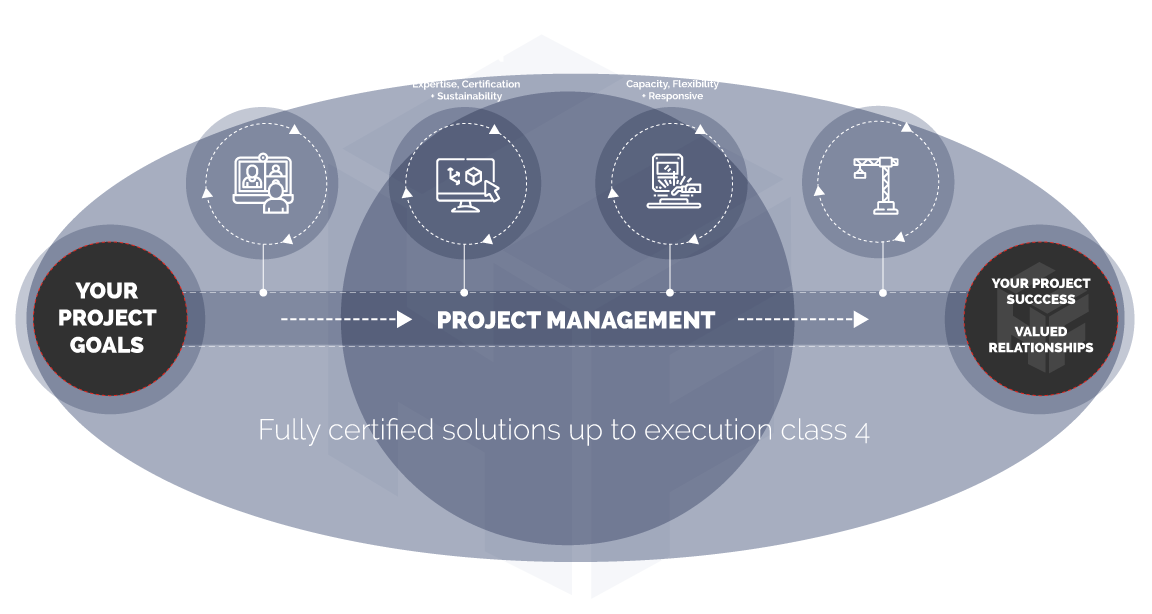

Project Management

Turnkey Projects

Slide

Our highly skilled team of multidisciplined experts work together to offer a range of integrated services and turnkey solutions, from concept design to completed project delivery. This includes project management, site survey, structural design and engineering, material supply, steel & aluminium fabrication, surface treatments and installation.

Since 1993, Had Fab has captured a wealth of experience in providing fabricated steel solutions to the Power Transmission and Distribution, Energy, Rail, Civils & Infrastructure, Commercial and Industrial Sectors.

Recognised as a trusted engineering project delivery partner working closely with key sector DNOs, operators, consultants, OEMs and principal contractors and Supply chain partners.

Operating from our head office and facilities in East Lothian, Scotland and following multimillion-pound investment across our four sites – Had Fab boasts unparalleled facilities and equipment. In total, the sites cover an area of over 55,000 square metres, including extensive storage space and two 120m long covered manufacturing lines. From here we serve our customers throughout the UK and overseas.